Installation

Characteristics of Tupress

Saves Working Time

Simply insert a pipe into a fitting and press it with a tool, then the work is completed. Conventional piping of bolts, nuts, and welds takes a long time, but Tupress system is simple and saves time.

No skill is required

In conventional plumbing, the workers are required to have special skills and cautions. Anyone can apply Tupress system with no special skills.

No fire is required

Since there is no fire at the piping site, there is no risk of fire. It is suitable for piping for house repair.

Becomes a completely clean facility.

Bolts and nuts system use cutting oil and compounds when soldering, which can cause metal contamination. Press type Tupress system will help you to build a clean facility.

Lightweight piping is now possible.

Using thin stainless steel, lightweight piping is possible for tall buildings. The inner diameter of lightweight piping is wide and the waterflow is large.

Samyoung Metal's strict quality inspection (self-inspection for water pressure of 40㎏/㎠) helps you to prevent risks of water leakage

※Caution - If ground water is used for stainless steel piping, piping may be adversely affected.

Standard Cost Estimation

Press Fitting Type (perm)

Commentary

- This estimation is a standard general piping estimation for neck's inside of press fitting type stainless steel pipe.

- Marking, boxing, inserting, installing supporting metals, cutting joints, minor transportation, and water transportation includes estimation. However, since insulation stanchion and tube stanchion are excluded in the support facility installation, they are appropriated separately.

- On this estimation, add 20% for toilet pipe and 30% for machine pipe.

- For outdoor piping (inside the culvert), decrease 10% from this above-mentioned amount.

- For floor heating piping, increase 10% from this above-mentioned amount.

- If the walls are peeled and maintenance work is required in the indoor pipes(except for the floor heating piping), it can be increased within the range of 10% of the above-mentioned amount.

- Excavation, Refilling, and residue treatment for tube attachment are separately included.

- If bending is required, it is added separately to the above-mentioned amount.

Specifications

Responsible construction will be ensured by giving a construction briefing session to all the workers before the piping construction.

Applicable Standards

Stainless steel pipe for general piping (KS D 3595) 15SU ~ 100SU

Application Scope

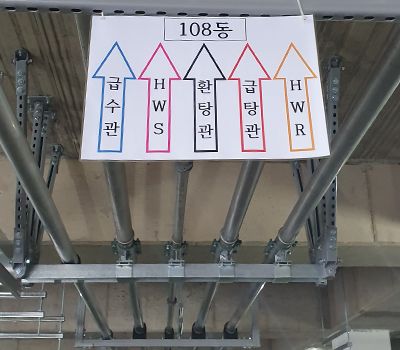

Underground water supply pipes, water supply and hot water supply pipes inside buildings, heating and cooling pipes, fire-extinguishing pipes, electric pipes, air pipes, etc.

Materials and Quality

STS 304, KS B 1547, KS D 3595

Construction Method

-

01 Cut Pipes

Cut the tube so that the end of the tube is at a right angle. Use a cutter (B) specially-designed for stainless steel

A : Pipe cutter

A : Pipe cutter

B : Stainless steel-cutter

B : Stainless steel-cutter

C : High-speed cutter

C : High-speed cutter

-

02 Remove Burr

After cutting with the high-speed cutter shown in Fig. C above,

the burr should be thoroughly removed with a burr-remover, file (steel sharpener), etc. Remove Burr

Remove Burr

-

03 Mark Line

The pipert, EQ line marking is displayed below. Mark the line with a special pipert, EQ line marking ruler.

If there is no pipert, EQ line marking ruler, remove the o-ring from the socket and use that socket as a line

indicator. Mark the line mark so it can be seen after the pipe has been pushed into the joint. Line Mark

Line Mark

Before inserting the

Before inserting the

pipe until the line mark After inserting the

After inserting the

pipe until the line mark -

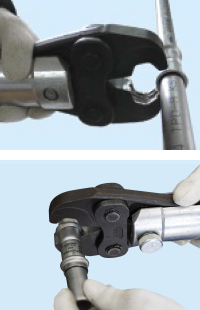

04 Pressing Procedure

Insert the pipe to the end of the joint, check the line mark again, and then press it. For pipert fittings,

crimping tools recommended by Samyoung Metal must be used. By performing crimping tool inspection

periodically, it is possible to prevent the construction failure due to aging of the crimping tool. Before pressing

Before pressing

After pressing

After pressing

-

05 Check Pression

Use a hexagonal gauge to check the parts and the sum of the compression.

Check compression

Check compression

-

06 Test Water Pressure

The pipe corresponding to the water supply device shall test the water pressure specified by the water works

authority (15㎏/㎠). The pumping pipe shall be double the pressure corresponding to the process before

pumping, and other details shall be in accordance with the standard specification. Remove air completely to

prevent danger, then apply pressure

Construction Precautions

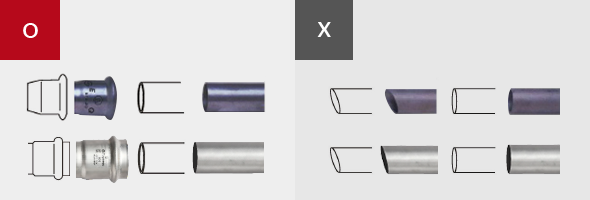

Do not damage the rubber ring.

Cut off the deformed pipe and completely remove burr.

Push the pipe fully into the line mark.

Check the line mark before pressing and push it in sufficiently

Do not make a compression mistake

(The special pipert tool is necessary)

- For adapter part construction, screw parts must be conducted first and then the curl part should be pressed

- When buried in polluted soil such as animal shed, farmland, garbage landfill, corrosion by microorganisms may occur. In order to avoid this, it should be buried wrapped with vinyl or tape after a soil research and perform flow tests.

- If left without water flow for a long period in underground burial, it may cause chemical reaction due to water content, ventilation, etc., which may cause corrosion. It is important to flow water as soon as possible.

- Using materials containing chlorine or sulphide attachments maycausecorrosion. lnordertoavoidthis, wrap vinyl ortape.

- Do not let straight pipes drop or touch heavy objects during the transportation or during the piping work, especially the part connected with the pipe joint should not be deformed.

- Stainless steel pipes should not be hung with steel wire. Pipes should be transported with nylon wire and cloth band. Also, large caliber pipes should not be hung with steel wire.

- During temporary storage, cover stainless steel pipes with vinyl cover or security cover.

- For a proper storage, a place where the stainlesssteel pipe would not be damaged by falling objects is to be selected. Do not store in contact with gas pipes or reinforcing bars.

- Fittings should be kept in plastic packed state at all times. When inserting the pipe into the joint, be sure to clean it before inserting it.

- When inserting the pipe, insert the pipe and components straight so that the rubber ring would not be damaged. If the pipe cannot be inserted smoothly, insert water directly into the rubber ring part.

- When pressing, fit the groove of fittings to the groove of the jaw, and press the tube so that the jaw is perpendicular to the groove.

- It is recommended to mark the compressed part with a marker to verify the compression.

- Do not apply any physical impact by throwing or dropping when using the jaw.

- For Tupress, crimping tools recommended by Samyoung Metal should to be used.

-

Precautions for Groundwater Use

- When groundwater is used, special care is required because microbial corrosion (MIC) is likely to occur

1) Landfill, coastal regions, and industrial areas are subject to chlorine-caused corrosion.

2) There is high probability of occurrence in summer due to high temperature and humidity

- Prevention Methods

1) Flow water after water quality testing

2) Use portable water

3) Install water purification facility

4) Insert corrosion inhibitor

※ We a re not responsible for defects due to failure to follow the instructions.

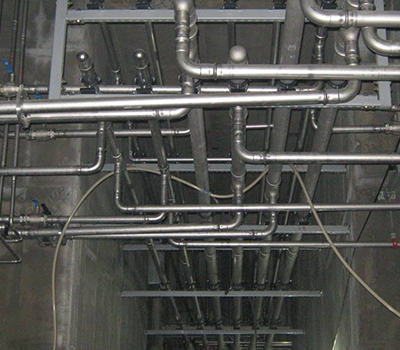

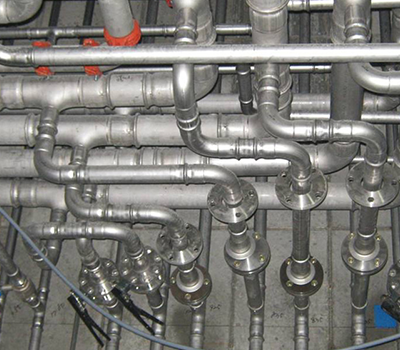

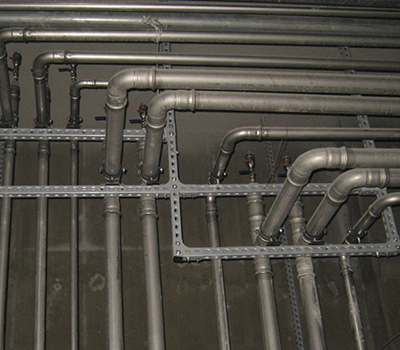

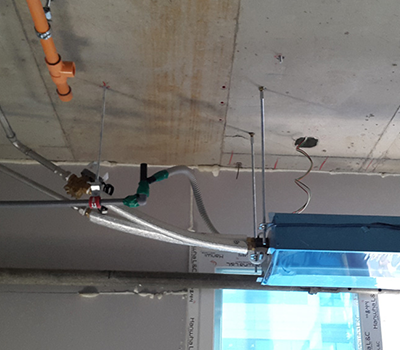

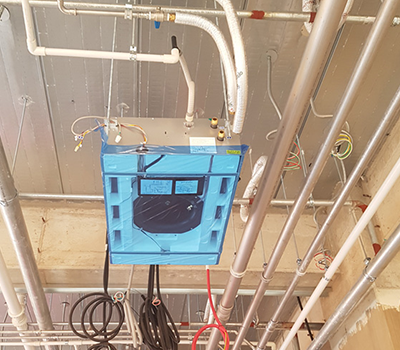

Photos

Tools

Battery-powered pressing tools

mini, RP318, press ACC, medium, medium+, big, stainless cutter

-

01 mini [15SU ~ 25SU]

01 mini [15SU ~ 25SU] -

02 RP318 [15SU ~ 60SU]

02 RP318 [15SU ~ 60SU] -

03 press ACC [15SU ~ 60SU]

03 press ACC [15SU ~ 60SU] -

04 medium+ [15SU ~ 80SU]

04 medium+ [15SU ~ 80SU] -

05 big [75SU ~ 100SU]

05 big [75SU ~ 100SU] -

06 stainless cutter [15SU ~ 100SU]

06 stainless cutter [15SU ~ 100SU]

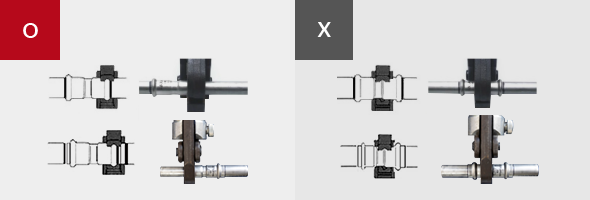

Jaw used only for pipert

Cautions when using rechargeable crimping tool

- Before and after usage, clean the jaw and the machine, and check for any abnormality (damage or wear such as holes, gold or grooves). Clean the jaw with jaw-specific oil. Clean the machine's body with air or damp cloth with neutral detergent, and then dry it

- If the battery is discharged during use, cool the heat of the machine for at least 10 minutes and then use it again. (Continuous use of a tool without a break can cause the machine to be over loaded and result in defects.)

- After 10,000 presses, send the instrument to the designated service center for inspection. (Annual inspection is recommended)

- If oil leaks from the machine, do not touch it

- Wear protective glasses during usage.

(2Hz)

(5Hz)

reach

temperature

20 second and

flashes intermittently

Battery

Lifetime